PRATI – Label meets flexible Packaging

It is no longer a secret that the two areas of label and flexible packaging are increasingly merging. The current Prati technology supports this trend.

Experienced label printers have long been trying to establish themselves in the field of flexible packaging. Against the background – even there – of ever smaller job sizes, shortest product life cycles and increased cost pressure, fast set-up and maximum flexibility are becoming more and more important in this area. Classic packaging printers are also increasingly interested in compact technical solutions for ever smaller job sizes.

Constantly growing demand

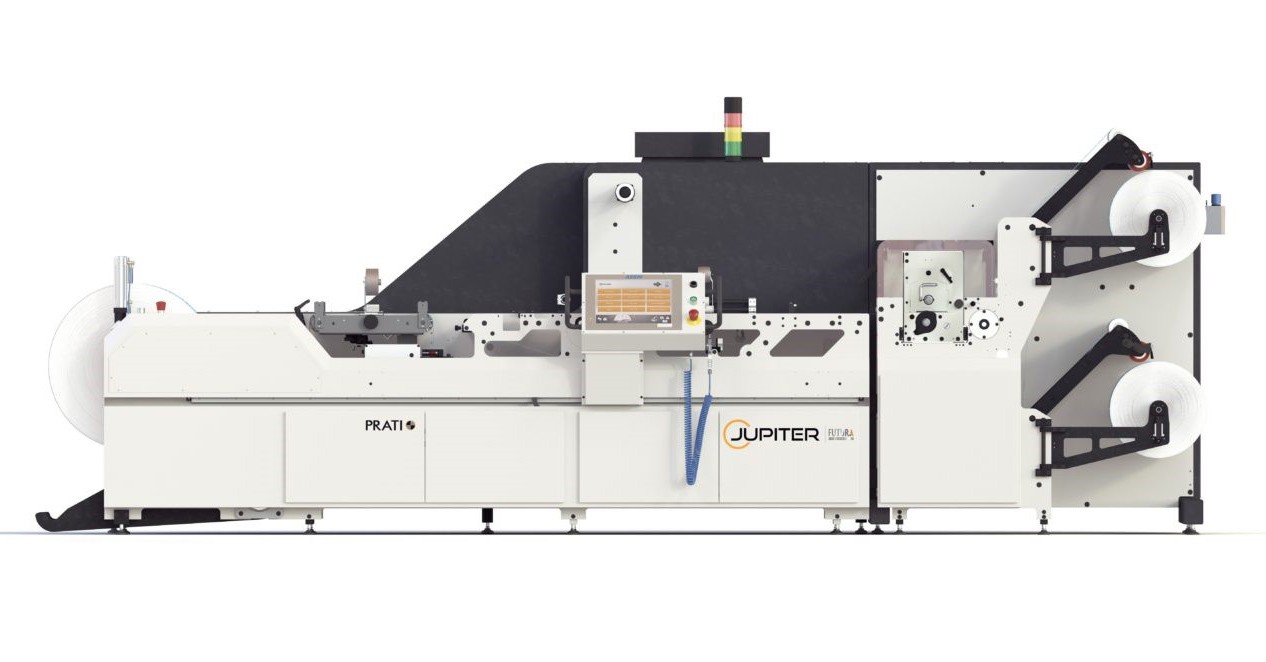

As a logical consequence, a constantly growing demand for this area of finishing is developing among manufacturers of conversion machines. With the further development of the Jupiter series, the Italian manufacturer Prati has developed a machine that specifically meets these requirements and can also be ideally used as a finishing system for checking, cutting and winding labels. “It is remarkable how the number of projects in this market segment has increased over the last 2-3 years. It helps when your own machine supplier takes this growth into account by developing machines designed specifically for this purpose. The two web widths 630 and 670 mm, the fully integrated 1100 mm unwind and 800 mm rewind clearly show that this machine was developed for the flexible packaging sector. The fact that the developers were also looking for higher mileage is underlined by the maximum production speed of up to 400 m/min.

Equipped with computer intelligence

In order to be able to use these high speeds in practice, the press was equipped from the outset with the necessary computer intelligence to be able to communicate with all the usual manufacturers of workflow providers. The machine only stops to eliminate or correct predefined errors. This method of operation ensures maximum accuracy and reproducibility and the production process is not interrupted unnecessarily.

With integrated camera system

This task can, as is common for many users, also be performed by means of a built-in camera system. The machine is designed in such a way that even at top speed there is enough “braking distance” to position each defect precisely in the desired repair area. In addition to a “normal” splice table – as we know it from label production – the Jupiter can optionally be equipped with a vacuum table for this splice area. This makes it easier for the machine operator to splice the thinnest films and ensures a high level of process reliability.

Precise and fast cutting technology

In addition to a slide-out knife cassette with shear and razor blade knives, there is also the proven Fastcut system, in which up to 18 knives are positioned within seconds and, above all, securely with a highly accurate linear spindle. This technology is becoming more and more a “state-of-the-art” technology and offers a multitude of advantages. The Prati Jupiter can also process multi-substrates from 12 to 450 µm. To be able to process this wide variety of materials safely, not only a sophisticated servo technology but also the most difficult voltage control is required. Even the standard model of the machine is supplied with friction shafts to ensure that the various requirements for different voltage settings for thin mono materials, SK labels and clear-on-clear labels can be met.

Cutting the thinnest webs

An important aspect is to be able to separate also during the winding process. This is why it is possible to process webs separately from each other without the risk of telecopying by means of dual winding and pneumatically controlled loading arms. The rewind area is rounded off with a “2-spindle carousel”. Here, secured by a laser safety barrier, the possibility is created to work as with a 2-spindle turret. This means that despite the separation of the rewind on 2 spindles, the advantages of a 2-spindle turret are not lost.

Prati Jupiter 630/670 – Technical data

Max. recommended working width: 630/670 mm

Min. material width: 300 mm

Maximum speed as slitter rewinder: 400 m/min (depending on job)

Ø unwind shaft: 76 mm

Ø unwinding max.: 1100 mm

Ø max. take-up diameter upper take-up shaft: 800 mm

Ø max. take-up diameter lower take-up shaft: 800 mm (optional)

Equipment: Integrated roll lifter, friction shafts, dual rewind, vacuum splice table, automatic knife system, 2-spindle turret