GM – The little finishing sister – GM DC350Miniflex for the entry

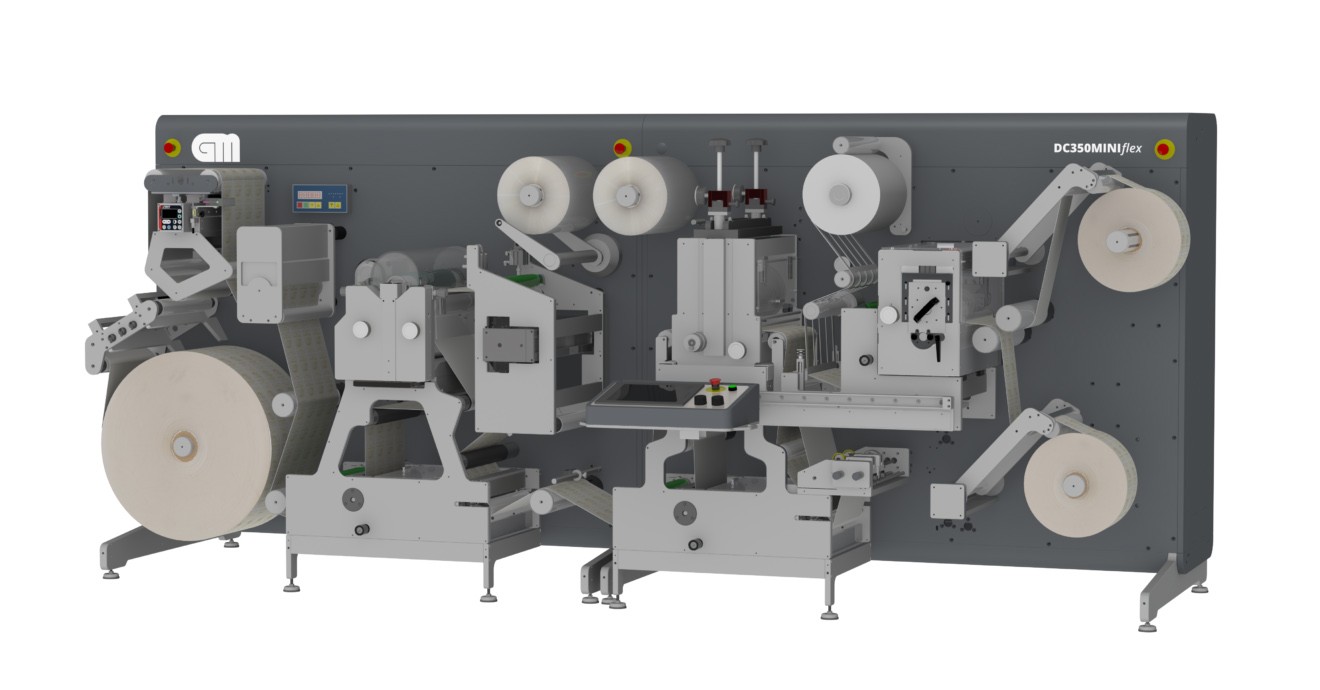

The presentation of the new DC350Miniflex in April 2020 by the Danish Grafisk Maskinfabrik A/S (GM) is a good reason to introduce the “little” sister of the DC350 with its options and possible uses for a wide range of applications.

The new DC350Miniflex from Grafisk Maskinfabrik A/S is a compact alternative to the DC350 and a further development of the DC350Mini. This new introduction to GM’s portfolio with its wide range of options thus joins the DC350 family.

Cost-effective alternative

GM is thus consolidating its position in the premium segment and offers a cost-effective alternative to the well-known DC350. The line has been designed according to the latest technological and ergonomic aspects and meets the industry standard 4.0. Also available as DC350Miniflex with an extended web width of 550 mm. The basic machine is already equipped with a semi-rotary die-cutter, Flexi printing unit (optional semi-rotary) for applying varnish, dual winding and VPN gateway for remote maintenance of the DC via a secure internet connection. The compact design in comparison to its “big” sister, the DC350, makes the solution attractive for companies with a small footprint who at the same time do not want to compromise on equipment and functionality.

Standalone or integrated

The new DC350Miniflex can be configured as a stand-alone press and as an integrated postpress (“inline”) for all common digital presses. Here too, GM has gained experience through cooperation with manufacturers of digital printing solutions and is in close contact with its customers to continuously improve products.

Modules for diverse applications

A major advantage of the new solution is the many expansion possibilities offered by the open and modular concept. SmartLam is an option for producing multilayer labels (multilayer labels) in the DC. Efficient production of these products requires either a “crossover” unit in the press or lamination of two pre-printed webs in register. The advantage of lamination is that the full web width can be used, doubling production capacity, but also allowing labels to be produced in larger formats. During the production process, up to 72 m/min two webs are laminated in register using servo control. SmartSlit is a fully automatic knife system to reduce makeready times and to precisely adjust the knife unit to the substrate. Not only the fast adjustment of the knives, but also the accuracy provide production reliability, time savings and higher quality. The SmartFlexo flexographic printing unit is based on the company’s “Flower” concept and enables register-accurate spot coating for pre-printed material. It is available in both full-rotary and semi-rotary versions. SmartStrip is a modified servo-controlled waste-matrix contact take-off system that ensures continuous tension and thus avoids production interruptions due to web breaks in the matrix. SmartLoad is a semi-automatic die plate change as another automation “tool” from GM (DC350 only). SmartTurret offers customers the ability to produce short runs efficiently with an automatic 2-spindle turret without the significant production stops associated with alternative systems. WebAdvance stands for fast roll change with single-spindle turret rewind. The cut webs are held during the reel change. These can be tied precisely and quickly to the new core. DoubleSpeedDie is the latest development from GM for a very fast die cutting process with up to 140 m/min in the semi-rotary production process (DC350 only). In the meantime, the first customers in Germany have already decided to use the new DC350Miniflex. A user report will follow.

Details about YouTube

With the new DC350Miniflex, GM has a good addition to its portfolio. The compact design and available options for a wide range of applications alone create a wealth of opportunities for the company and its customers. For more information, visit the “GM Tech Talk”, a new YouTube channel that clearly demonstrates technical aspects of GM’s finishing and converting machines. The channel builds on the long experience of Uffe Nielsen, CEO of Grafisk Maskinfabrik A/S and his technical team. The channel not only presents machines, but also discusses general technical issues related to finishing of labels and flexible packaging.

GM DC350Miniflex – Technical data

Modern platform concept with high flexibility

Maximum web width (DC350): 350 mm

Minimum web width: 50 mm

Winding diameter: 2 x 700 mm

Speed: Up to 72 m/min (140 m/min)

Operation: To