FlexRouter II

Manufacturer

IPTEFlexible, cost-efficient and fully automated depaneling

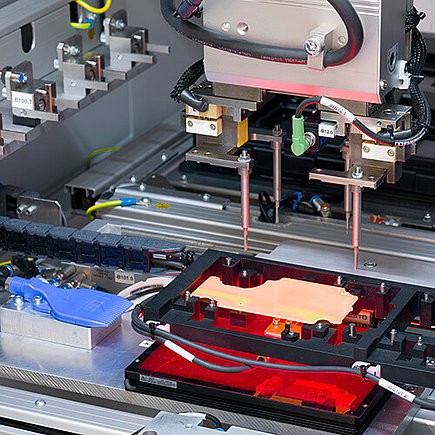

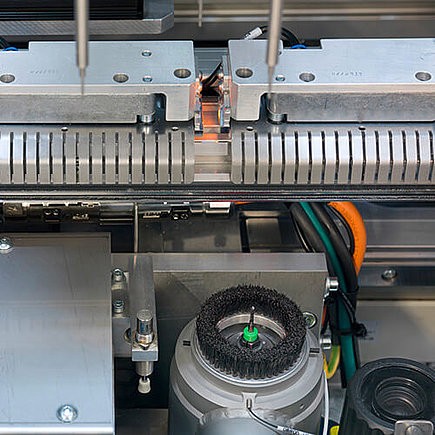

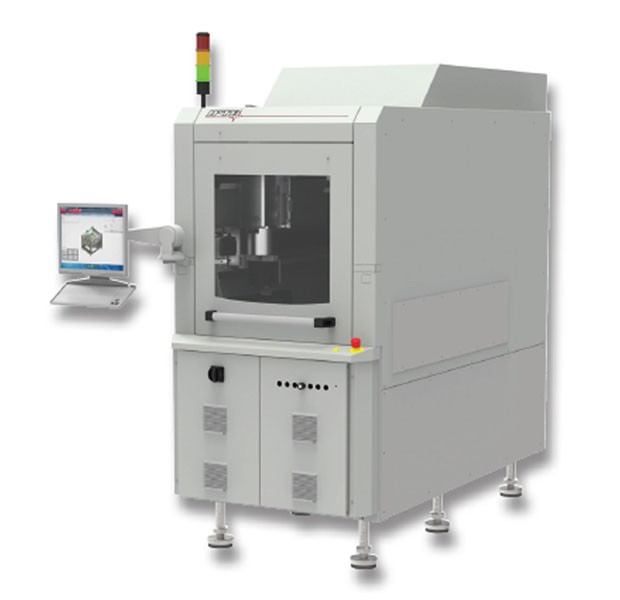

The highly successful IPTE FlexRouter II, globally tried and tested in numerous applications, has now been updated with a considerable number of new functions in the current machine series. By this innovative move, the greatly customizable depaneler featuring a very minimized footprint has become even more productive and cost-efficient. IPTE Factory Automation has introduced a new, uniform and intuitively usable machine-software environment for its router systems at present.

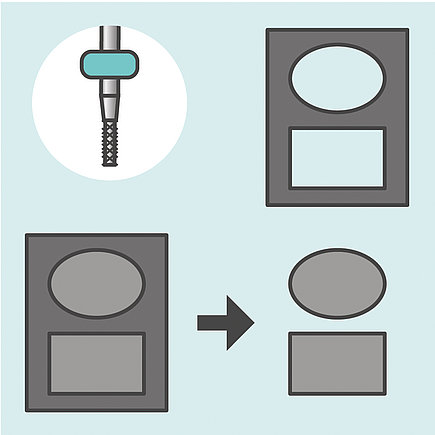

The FlexRouter II aims especially to middle-sized to high volume production lots fea-turing a high variety of different PCB versions, these are the demanding high-mix depaneling tasks based on short machine set-up procedures. Despite the very small footprint (machine width is only 500 mm), boards with sizes of up to 330 mm x 500 mm (length x width) can be processed without difficulties. Four of the seven machine axes in total are integrated as extremely precise linear drives of latest technology.

- High speed, low stress separating process

- Ideal for high diversity, high volume production

- High speed linear motor technology

- Flexible servo and pneumatic grippers

- Bottom side routing, top side gripper

- Small footprint

- Individual outfeed handling of the separated boards