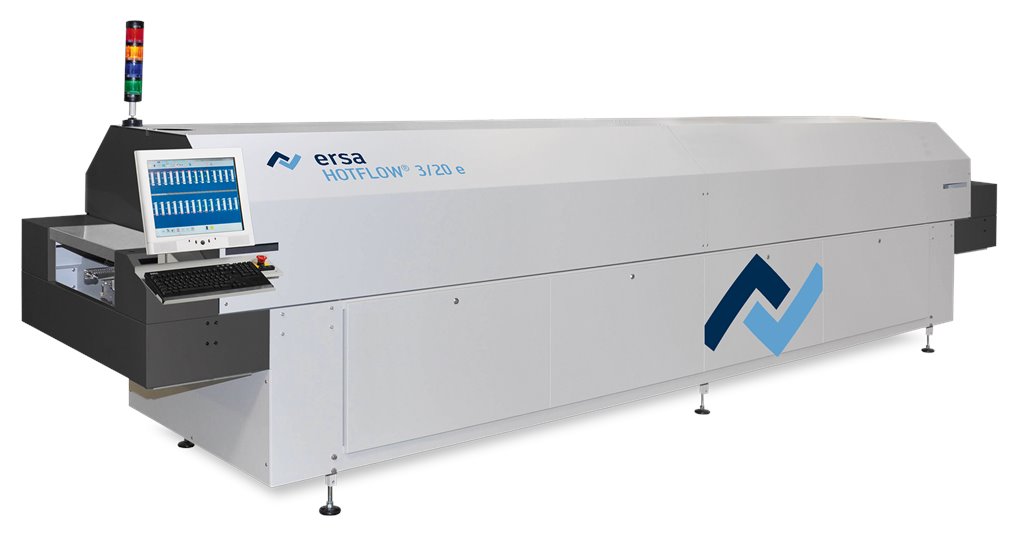

HOTFLOW 3/20e

Manufacturer

ErsaThe energy-efficient 10 zone reflow system provides a process length of more than 6 meters and is laid-out for maximum quality and minimal manufacturing cost.

The Ersa HOTFLOW 3/20e Reflow System is of robust design and manufactured entirely from steel, welded air-tight, powder coated and with interior electric cabinet and a PC operating terminal. Features include the motorized hood opening, quick-change convection heater cassettes, multi-level process gas cleaning and a powerful and effective cooling zone.

Highlights HOTFLOW 3/20e

- Excellent heat transfer with the most varied board assemblies

- Cost-conscious reflow soldering system

- Rest-oxygen monitoring and control with low N2 consumption

- Low energy usage through intelligent energy management

- Multi-level controlled cooling

- Multi-level process gas cleaning system

- “On the fly”-maintenance for increased system availability / uptime

- Single/dual track conveyor system

- Ersa Process Control (EPC) for continuous process monitoring

- Ersa Auto Profiler software for quickly generating temperature profiles

Options

- Pin-and-chain conveyor with low-mass center support

- Automatic adjustment of the conveyor width and the center support

- Up to 2 tracks with center supports possible in the system

- For single track systems, low-mass tubular supports are available

- Operating in ambient atmosphere, internal cooling with room air

- RPMs of fan motors are adjustable via frequency converters

- Pin-and-chain conveyor 3 / 4 / 5 mm pin length