POWERFLOW ULTRA

Manufacturer

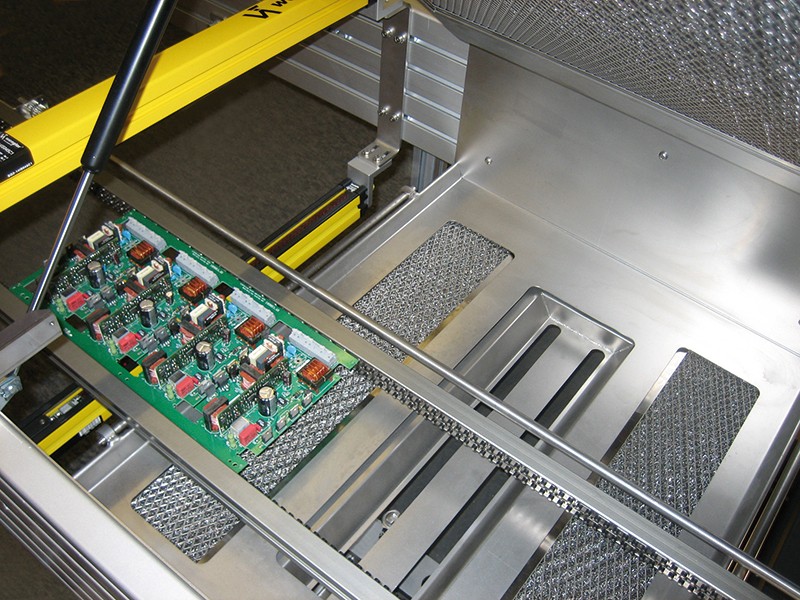

ErsaWith the POWERFLOW ULTRA Wave Soldering System, Ersa presents the ultimate solution for demanding lead-free wave soldering processes. This high-end product is based on a system concept with numerous future oriented and intelligent solutions, which will provide substantial added value to its users.

With its intelligent controls, the motor-driven fluxer is able to selectively flux specific portions of the printed circuit board. The modular, individually configurable preheat concept ensures a high rate of heat transfer. A multitude of wave formers guarantee excellent solder result regardless of the application. The robust tunnel design and the stable, welded frame underline the durability and the ease of access to the system for service.

Highlights POWERFLOW ULTRA – Full-Tunnel Wave Soldering System

- Superior process stability even at maximum throughput

- Precise, economical flux deposition through ability to program areas to be fluxed

- Modular preheat configuration for flexible and reproducible heat transfer

- Ideal solder nozzle combinations for all application requirements

- Prolonged cleanliness on account of continuous cleaning of the process gas

- Energy and cost efficiency through intelligent heating and nitrogen control algorithms

- Ease of maintenance because of excellent accessibility to all areas

- Robust, heavy duty, durable and automatically lubricated chain conveyor system

- Individual trace interface for transparent production processes

- Universal integration into existing peripheral equipment

- Databased, modern user interface: ERSASOFT 5

Options

- Finger conveyor

- Working width: either 330 / 400 mm

- Working width finger conveyor: 406 mm

- Maximum height of components, top of board 80 / 120 / 150 mm

- Split conveyor

- Programmable center support

- Spray monitoring of the fluxer

- Pyrometer control

- Dual solder module for different alloys

- Process gas cleaning

- Traceability