SMARTFLOW 2020

Manufacturer

ErsaThe little big one from Ersa in selective soldering: compact without compromises, extremely smart! Winner of the GTI Award 2015.

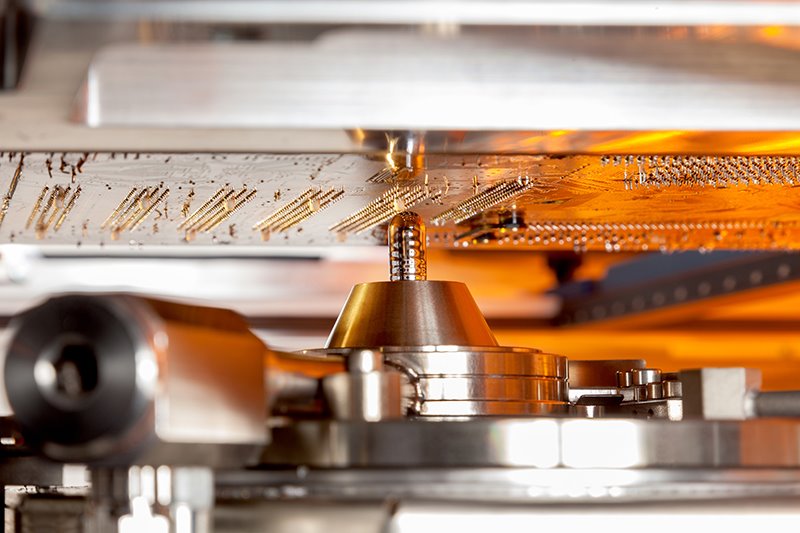

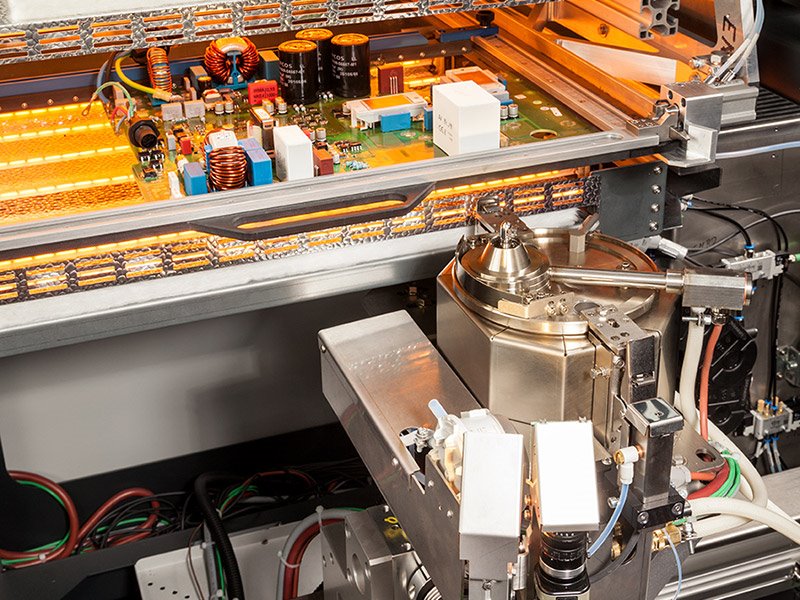

With the SMARTFLOW Ersa expands its range of products in this sector by a compact selective soldering system. With a footprint of less than 2.5 sqm the SMARTFLOW perfectly fits in productions with cell manufacturing. The semiautomatic operates in all process steps with the proven Ersa selective soldering technology, just like the larger Ersa VERSAFLOW models, suffering no comprimse in regards to quality and accuracy. The universal pallet mount allows processing boards with the size up to 508 x 508 mm.The fluxer performs with the highest positioning accuracy and with the least amount of flux deposition.

Features like spray jet monitoring or the process monitoring camera provide for process safety. Like the VERSAFLOW model range, the SMARTFLOW is equipped with a all-over preheating. The lower heater is furnished with eight emitters, which can be switched in groups so that the power consumed can be adapted to the heat demand and the size of the board. The upper heater has completely been overtaken from the lower heating is optimally adjusted to it. This ensures an efficient and reproducable through heating even for most complex component like multi-layer or heavy-mass.

Moderne process visualisation with ERSAsoft 5

The SMARTFLOW is the first system to be equipped with the modern ERSAsoft 5 operating software. This new version of our time-tested machine software impresses with its user-oriented

structure in addition to modern visualisation. Thanks to individual user interfaces, every user group gets the required data and information at a glance. Another highlight of the software is the picture in picture function (PIP) in combination with the process monitoring camera. Soldering parameters and a live process picture are available at a glance on the 24” touch-screen, which makes working on the machine ergonomical and clearly arranged.

Highlights Selektive Soldering System Ersa SMARTFLOW 2020

- Compact without compromises

- Modern process visualisation with ERSAsoft 5

- Convenient PC control with swiveling 24” touch-screen

- Ersa CAD-Assistent

- Use of Mini-Vario-Wave, Mini-Dip and area nozzles

- High ease of servicing

- Drop-Jet Fluxer with integrated monitoring

- Highest positioning accuracy and process

- All-over heating IR preheating lower/upper (scalable)

- Low energy and N2 consumption

Options

- Preheat bottom/top side: short-wave, dynamic IR emitters

- Emitter control for top and bottom heating

- Process monitoring camera (picture in picture system)

- Barcode scanner (2D handheld)

- Take-over of PCB data from CAD systems; programme creation (CAD assistent)

- Automatic soldering wire supply

- Different solder nozzle diameters

- Nitrogen heating

Request information material by e-mail