VERSAGUIDE

Manufacturer

ErsaPrevention of assembly errors by means of visual verification.

VERSAGUIDE – available as Elite, Pro and Ultra

VERSAGUIDE Elite provides support and control during PCB assembly or assembly work. The system avoids assembly errors and thus saves costs for complex reworking. The smart camera of VERSAGUIDE Elite has its own processor and does not require an additional PC.

Functions

- Check for similar parts

- Color inspection

- Step-by-step instructions, check for wrong parts

- Structure inspection

- Check of character strings for barcodes

- Recording of the finished work

Advantages

- Uses image recognition to prevent errors

- Easy to operate as an all-in-one system

- Supports digitization of your workplace

Image recognition software is used to set and monitor the criteria to be checked, features such as character strings, patterns, colors and textures are reliably recognized. Individual components or assembly instructions can be read in and provided as an image. VERSAGUIDE Elite guides the user through the work steps and provides immediate feedback. Only when everything is correct, the next step follows. Log data is saved for each work step, and the serial number can also be stored via a barcode scanner.

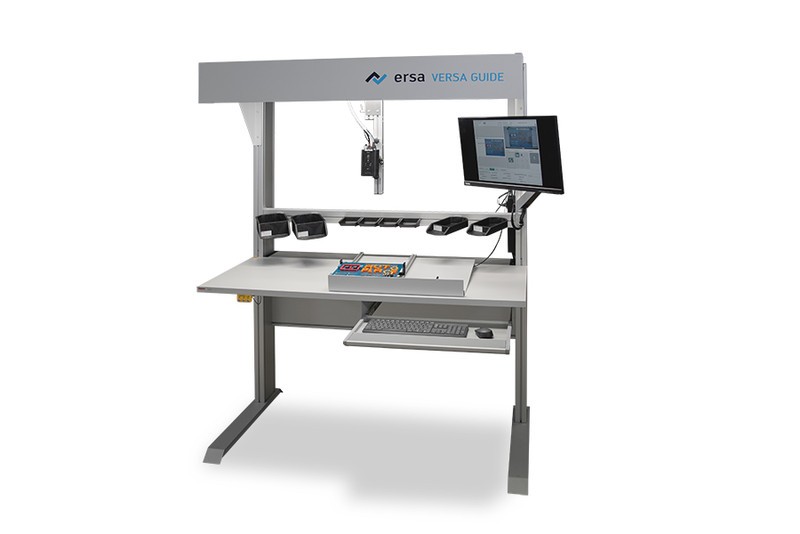

VERSAGUIDE Elite can be set up as a single camera system for existing workplace concepts. Or Ersa can supply the complete VERSAGUIDE workstation as required and with additional accessories such as accumulation roller conveyor, barcode scanner and excavation unit.

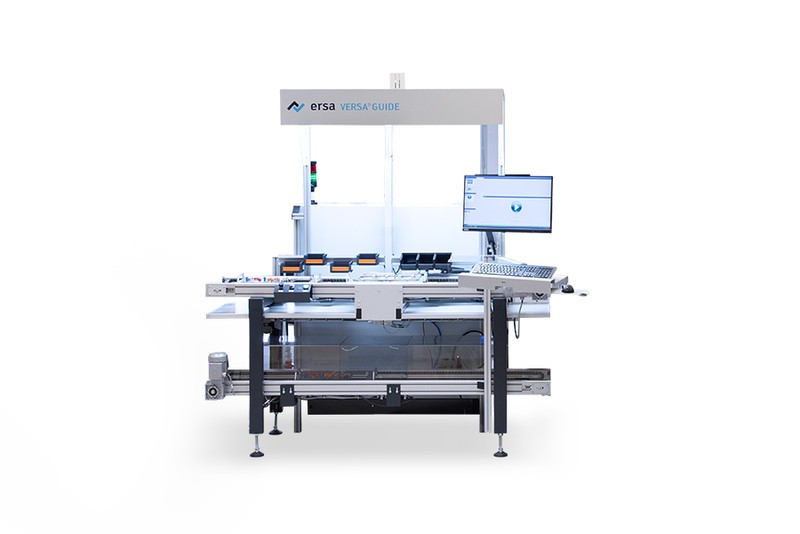

VERSAGUIDE Pro is Elite´s major expansion stage and helps in the assembly of electronic modules by 100% inspection. By saving on rework, reducing complaints or training of non-expert employees, the added value remains on site. VERSAGUIDE Pro works with a high-resolution camera including lens and illumination panel. With a working distance of 1,200 mm between the camera and the placement level, normal work is possible without restrictions.

Once the component is mounted, VERSAGUIDE Pro checks in a few seconds whether it is the right component and whether it has been correctly installed. Individual features of the component such as position, color, contour or dimensions are decisive. The inspection takes place in the 640 x 480 mm camera field of view.