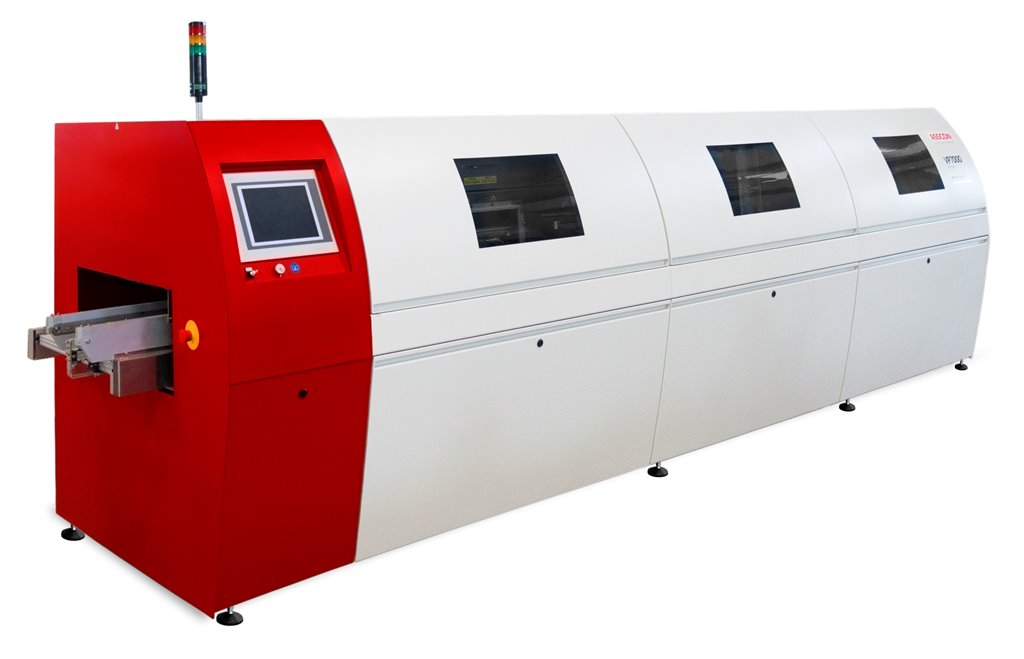

VP 7000 vacuum

Manufacturer

AssconThe Vacuum Inline Soldering System shows highest soldering quality at mass-production. Especially at the lead-free soldering application, the vacuum treatment right after the melting process grants void free soldered joints.

By the advantages of the progressive ASSCON Vapor Phase Soldering Technology with vacuum treatment, the quality of solderings reaches to a point which never has been reached before. The void free soldering has a particular relevancy for soldering joints with large surfaces and energy transfer. The system is made for integration in mass-production lines and it impresses with a very low energy con-sumption and operational safety.

Advantages

- void free solder joints by application of vacuum treatment of the assembly after melting

- oxygen-free soldering process in an oxygen-free vapor zone without use of protection gas

- suitable for lead-free applications without any limitation

- temperature gradients adjustable during the complete heating-up process

- reproducible process conditions

- no overheating or damaging of the electronic assemblies

- no shading, continuous heating-up of the assemblies

- reproducible temperature profile even with different assemblies

- no time-expensive preparation of temperature profiles

- soldering pastes with a low flux content are suitable

- even surfaces with a difficult wetting can be soldered correctly

- short heating-up time

- low energy costs by an intelligent energy management

- low operation costs

- operator convenience with microprocessor controlling

- Control monitoring and alarm system

- optimal accessible for maintenance and service works

- cooling system (optional) independent from external cooling water supply

- automatic operation in a production line (SMEMA-interface definition)

- Production utilization according ISO 9000 is possible (interface optional)