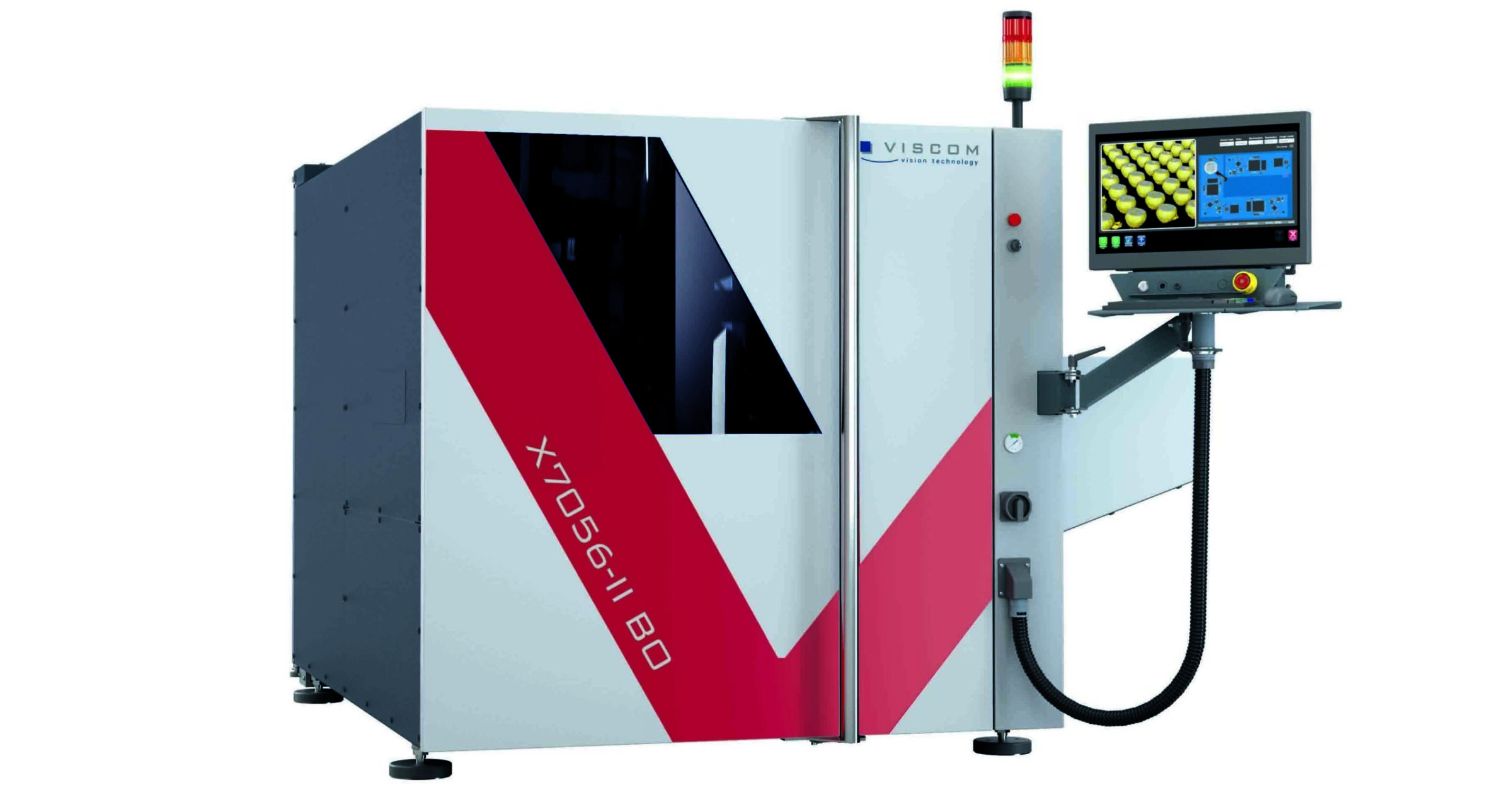

Viscom – New inline X-ray system X7056-II BO for high-throughput wire bond inspection

The role of power electronics is becoming increasingly decisive in the automotive sector, especially for electric drives. Smooth functioning and long service life of power electronics ensure the necessary product safety and also the desired energy efficiency of electric vehicles and hybrids. In addition, new types of sensors and cameras provide even better protection for vehicles during operation. The new Viscom system X7056-II BO, which inspects bond wires optically and radiographically in an inline system at maximum inspection depth, ensures comprehensive inspection of power semiconductors and encapsulated sensor elements alike.

The new X7056-II BO inline system effectively combines optical wire bond inspection with X-ray inspection to reliably and precisely inspect even encapsulated wire bonds and concealed solder joints underneath chips. The unique combination of AOI and AXI in a single system ensures high-throughput handling to meet the highest cycle time requirements at maximum inspection depth.

Ribbons, thick and thin wires are inspected, as well as the soldering quality of dies. Thanks to the high-resolution sensor technology, the inspection scope covers all bond points and wires, open and concealed connection points, so that the quality of wire runs, dies and component layers, damage and position deviations as well as voids in surface soldering are detected with absolute certainty. For very effective test program generation, the standard library contains all relevant test samples for die bonds, ball-wedge, wedge-wedge and security bonds.

With the new bond inspection system, Viscom offers an ideal solution for the increasing demand for X-ray inspection in the bond area. The system is designed for use in the production of high-end electronics and is ideal for installation in final assembly for power electronics, circuits, sensor construction and packaging to ensure 100 % quality control. Viscom’s offering is rounded out by powerful verification and evaluation of statistical process control.