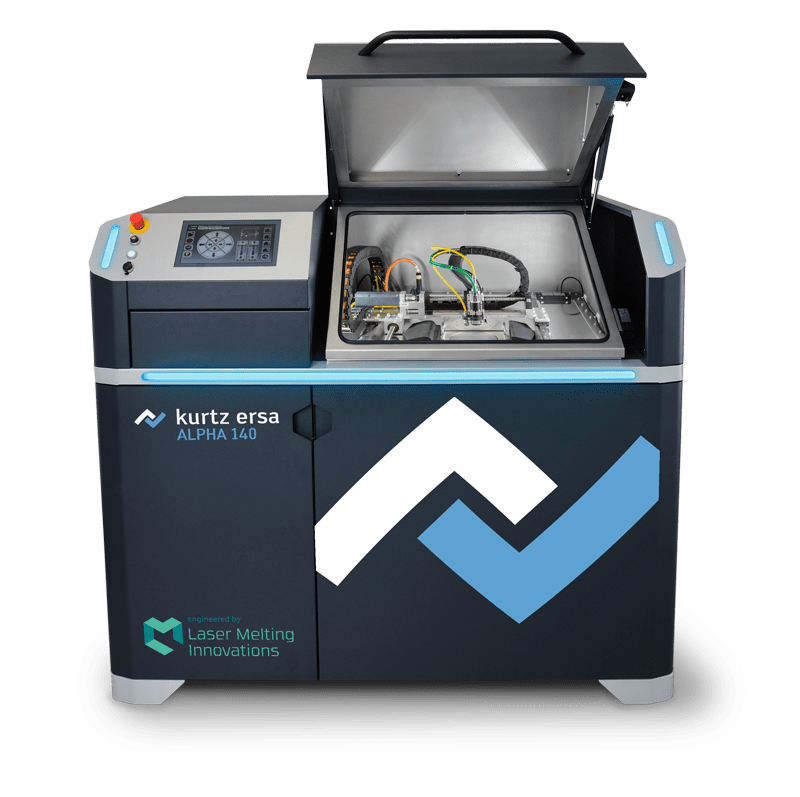

ALPHA 140

Manufacturer

KurtzALPHA 140

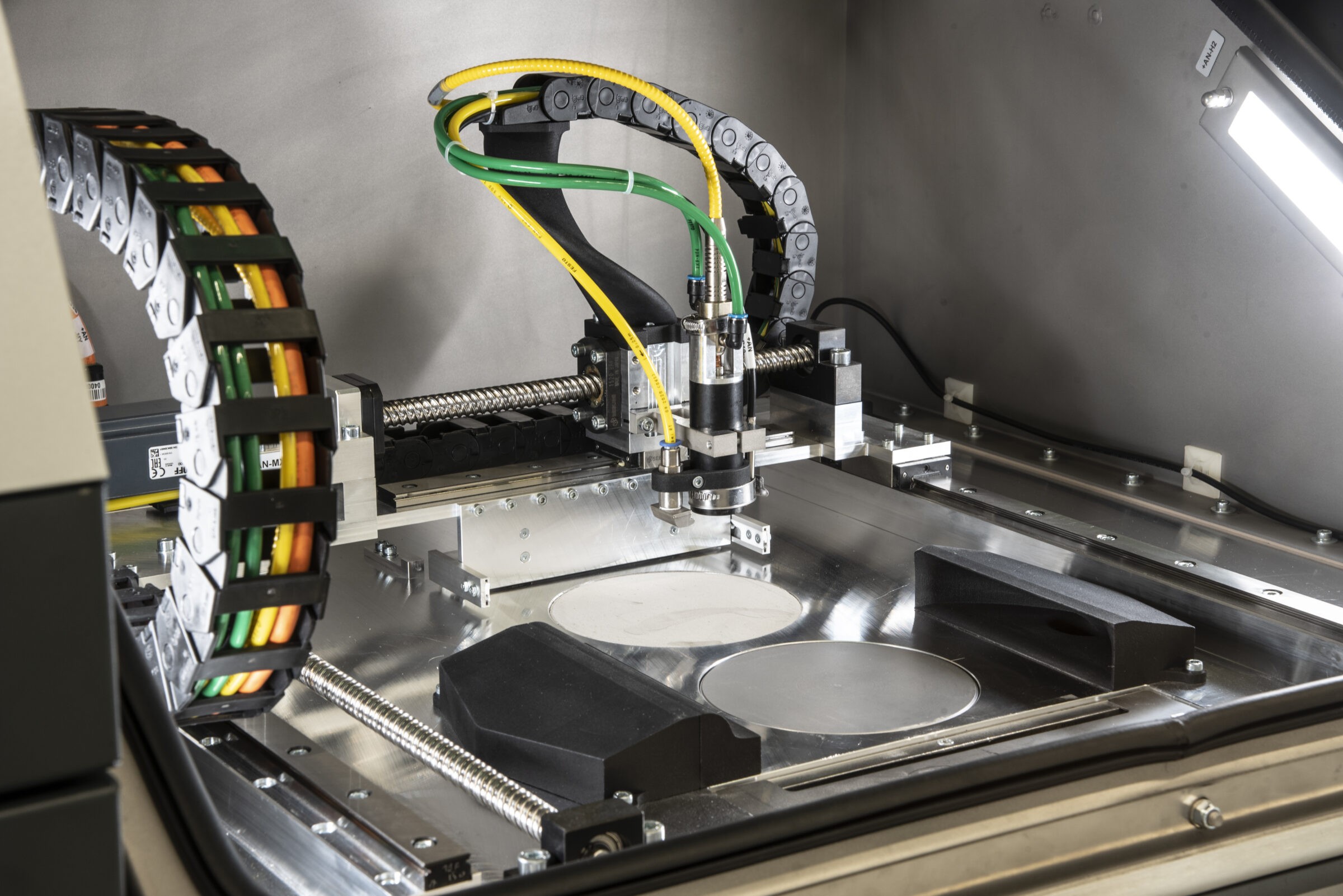

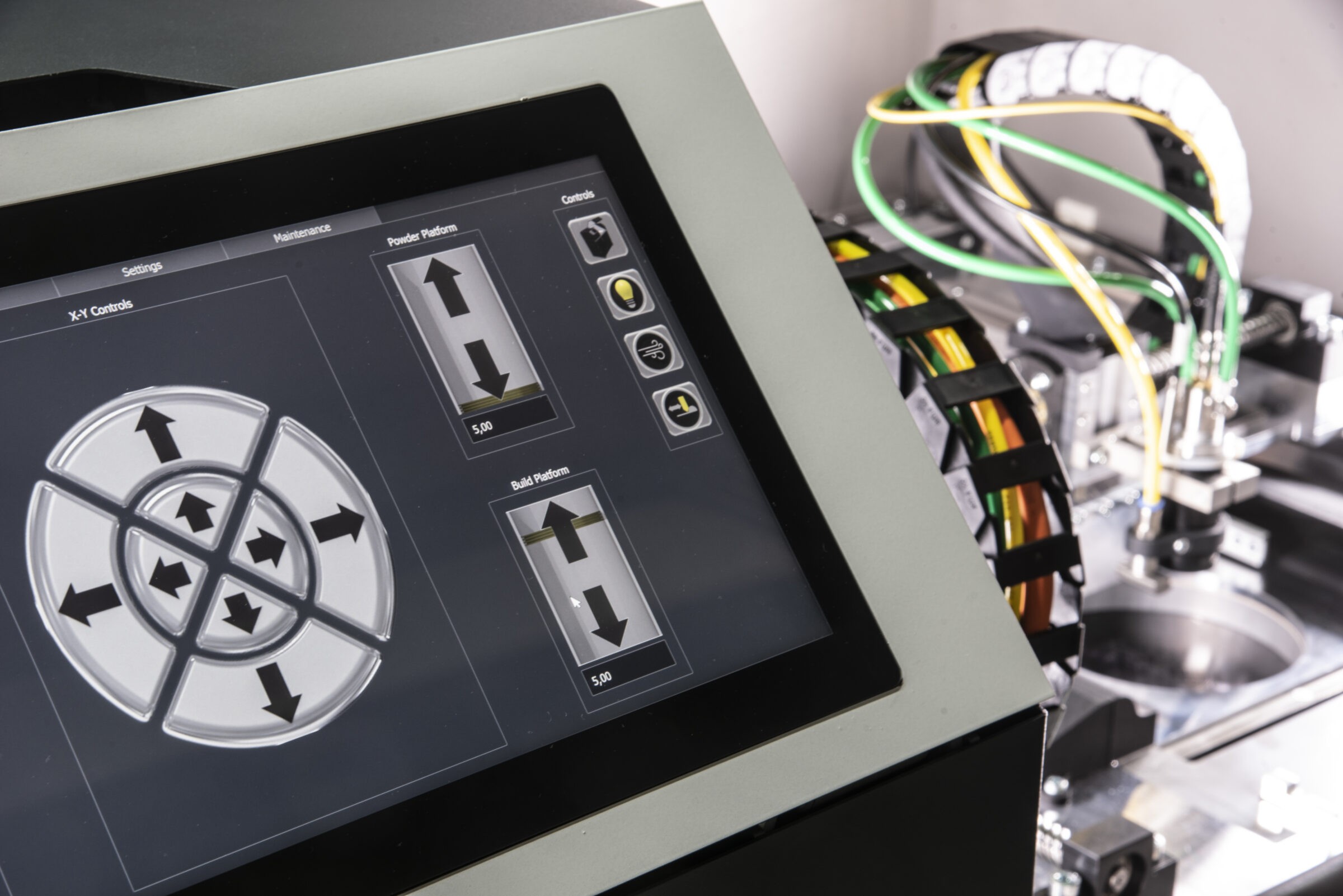

Additive manufacturing opens up enormous opportunities for megatrends such as lightweight construction and customization, as well as in industries ranging from electromobility to aerospace. The Alpha 140 metal 3D printer combines innovative manufacturing technology with simple operation and low acquisition and operating costs. Parts produced on the Alpha 140 achieve strengths comparable to those of conventional “laser powder bed fusion” machines and densities >99.5% while being up to 80% more economical. Additive manufacturing by selective laser melting (SLM) enables the efficient and economical production of functionally optimized metal components from many different alloys.

Whether producing tools or printing prototypes in small quantities, the advantage of 3D printing is freedom of form and variability. In contrast to CNC manufacturing, where the material is cut away from an original block, there are no large quantities of material pieces that subsequently have to be cleaned and disposed of. Only the material for the workpiece and necessary supports are needed, and the rest can be added back to the next production. Additive manufacturing, therefore, conserves important resources and thus also the environment.