VERSAFLOW 3/45

Manufacturer

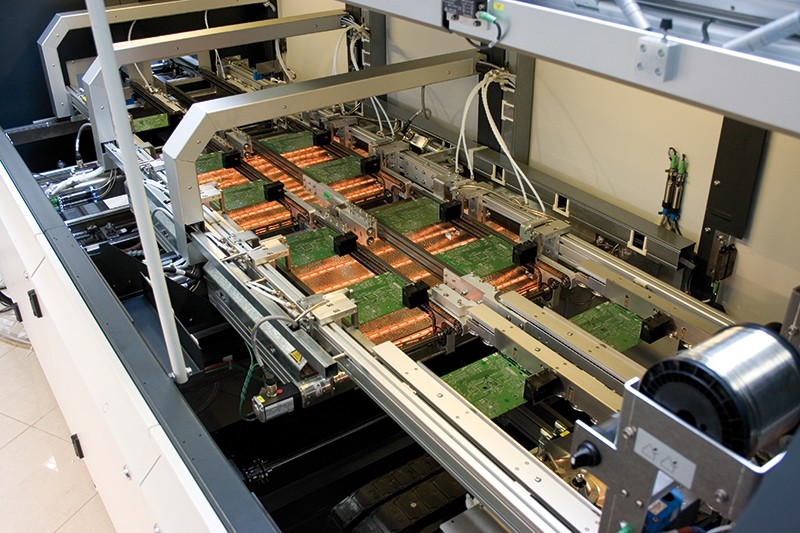

ErsaThe VERSAFLOW 3/45 is the first in-line selective soldering machine with dual track transport. Highest flexibility and highest throughput can be realised with the smallest possible required space.

In order to satisfy all demands in regards to flexibility, the third generation of Ersa´s VERSAFLOW selective soldering systems is based on a modular platform. Depending on the application and on the throughput requirements called for, additional flux, preheat and solder modules can be integrated into the system. In the maximum configuration level of the VERSAFLOW, the system can therefore operate with up to three solder modules, and each of these modules can again be configured with two mini-wave solder baths. In total, up to 6 mini-wave solder bath can be installed in a system, and each solder module can be preceded by a preheat unit.

Doubling the throughput rate, maximum expansion

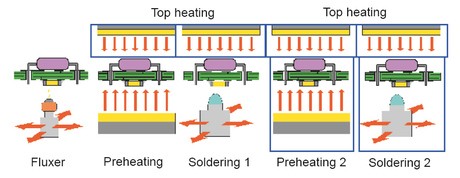

Multi-wave solder bath is available as an alternative to the single-wave bath. For configurations with the single-wave bath, additional top side preheaters are available for both the preheat zones as well as over the solder baths. With the dual-track option, the throughput rate can be doubled without increasing the footprint of the unit. If the size of the board assembly permits, the preheaters can be segmented, and this feature will further increase throughput. The VERSAFLOW offers its user a maximum of opportunities to configure his system. On account of the high throughput, the amortization period is rather short. With the Ersa VERSAFLOW, the highest throughput rate of any system currently on the market is achieved.

Highlights Selective Soldering System VERSAFLOW 3/45

- High end selective soldering system to integrate into in-line manufacturing concepts

- Mini-wave soldering for high flexibility or multi-wave soldering for high volume applications

- Product change without loss in production time with the multi-wave process

- Parallel process through separation of fluxing, preheating and soldering cycle

- Use of up to 4 flux spray heads

- Flexible system configuration on account of modularity of the design

- Ideal for linking to manual workstations or peripheral equipment

- Secure process control with monitoring of all relevant processes

- CAD-Assistant for offline programming

- Link for traceability systems for process control

Options

- Roller-type conveyor for direct board handling

- Programmable width adjustment

- Precision Drop-Jet Fluxer, up to 2 XY modules and 4 spray heads per module

- Maximum permissible board weight: 20 kg

- 2 different flux media for each module

- Up to 5 preheat modules

- IR preheater individually configurable, convection on lower and upper side

- Pyrometer to monitor temperature

- Up to 3 solder modules with each 2 solder bath for mini-wave and mini-dip applications

- Electromagnetic multi-dip-bath, modular construction

- Tool-change “on the fly” for multi-dip tools

- Controlled rest-oxygen value in multi-dip tool

- Combination of multi-wave bath and mini-wave modules

- Transfer of board data from the CAD system

- ERSAsoft 5, inclusive integration of MES (Manufacturing Execution System)