CK Nanovate Nickel prolongs the Life of the Stencil

Always striving to stay one step ahead in manufacturing, in particular in view of the continuing miniaturization of components, Christian Koenen GmbH has searched for a new high-tech material for its precision stencils.

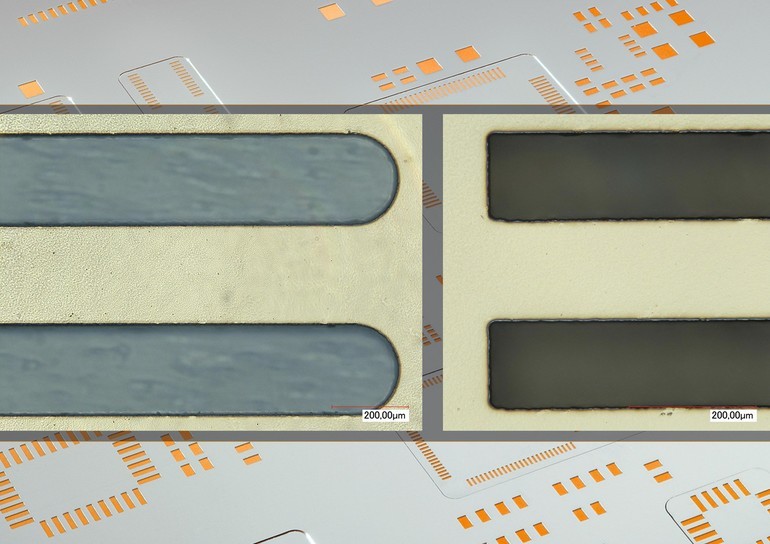

In the past few years, research and development in the area of the stencil material was ongoing. Especially the area of nickel proved to be very promising. With CK Nanovate™ nickel, the company has now included a tried-and-tested product from the field of aeronautics in the product range. Before its introduction, extensive tests had been executed in the Application Center. Some customers have also been using the material and test phases producing excellent results are ongoing. In particular, the fine crystalline grain structure and enhanced laser cutting properties of CK Nanovate™ nickel have to be highlighted, producing exceptional paste release properties, which Overall result in increased yields and lower costs. With sharper cutting edges on the printed circuit board, the print deposits are sealed much better. The stencil life is significantly prolonged thanks to improved hardness and ductility. Uneven printed circuit boards will not result in waviness of the stencil.

The new HighTech stencil material CK Nanovate™ Nickel is suitable for special applications and is a good addition to our product portfolio.