Electronic

Interflux - NH 1 solder wire for robot and laser soldering

Interflux® NH 1 is an activated no-clean colophony free and lead-free solder wire that gives fast and repeatable soldering results on a wide range of surfaces including brass. NH 1 provides fast wetting and low spattering making it particularly suitable for robot and laser soldering but also for normal hand soldering.

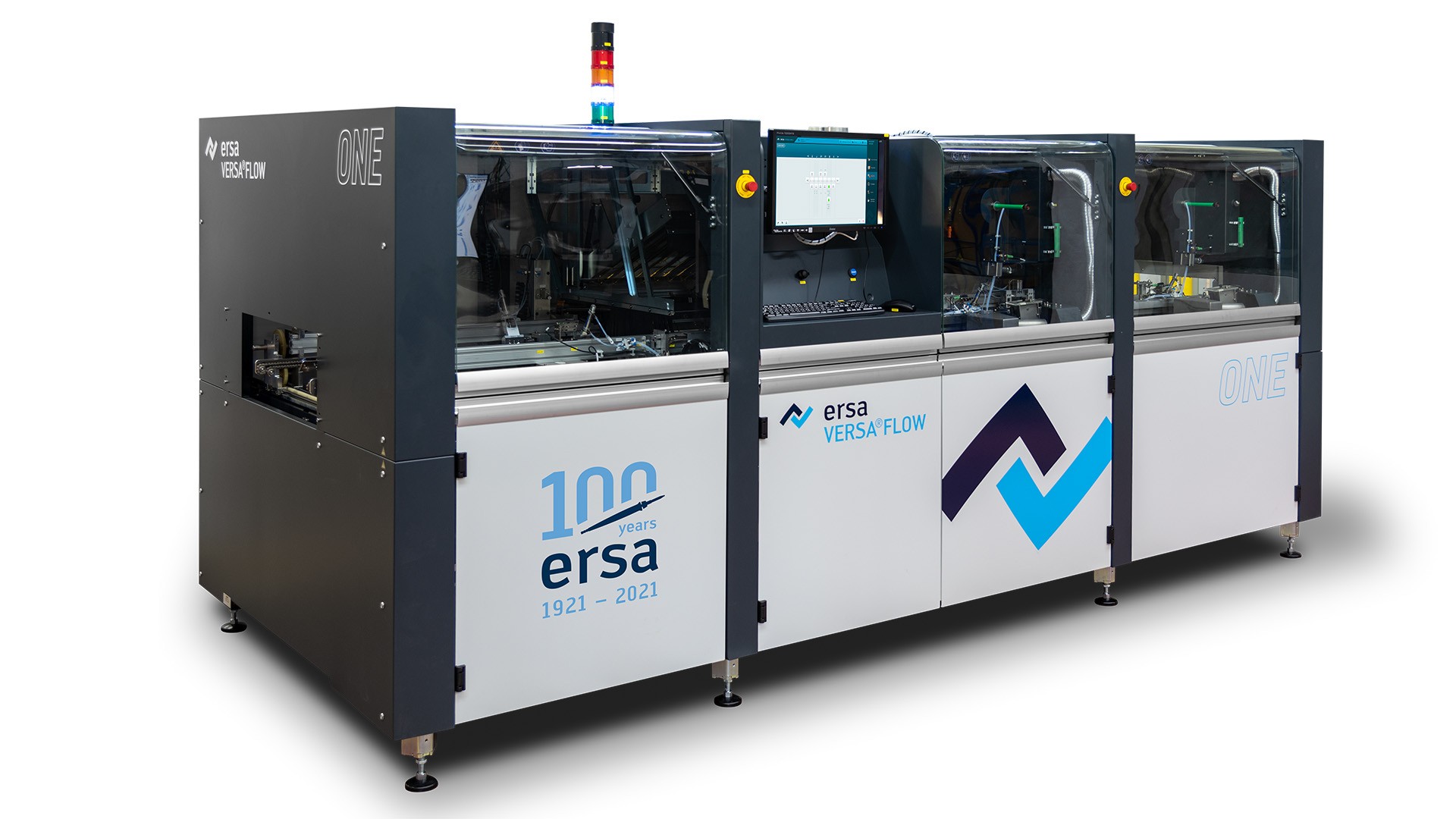

Ersa - VERSAFLOW ONE

Your entry into the excellence class of selective soldering: Top quality with a compact footprint - the VERSAFLOW ONE is the new entry into the portfolio of Ersa VERSAFLOW inline selective soldering systems. The system combines proven Ersa DNA and customer-oriented option structure with high availability at extremely attractive acquisition as well as operating costs.

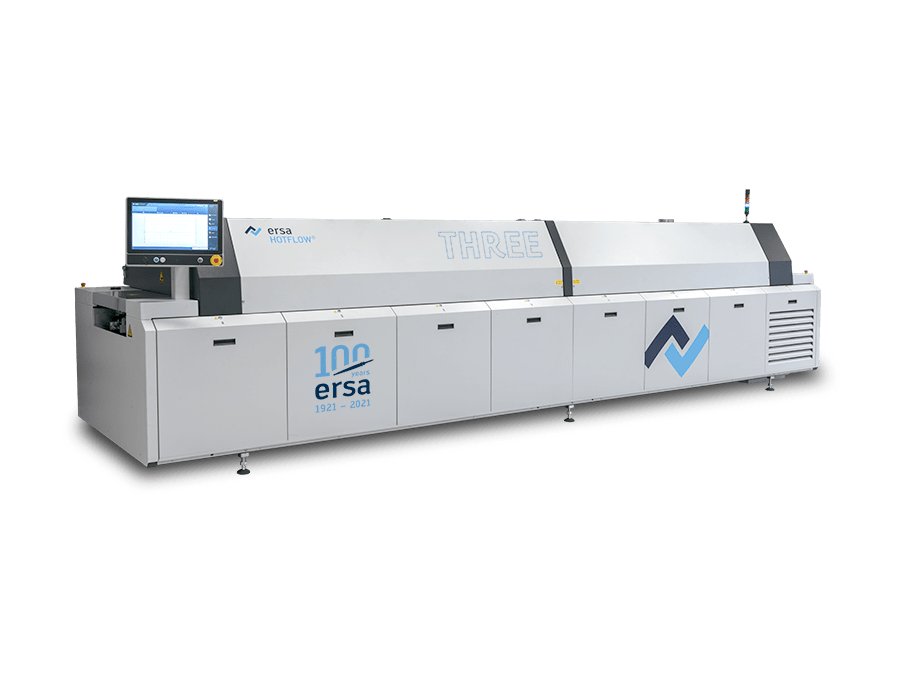

Ersa - HOTFLOW THREE

With the HOTFLOW THREE, Ersa makes a clear statement for even more quality in soldering. Absolutely unique selling point: the SMART CONVECTION POWER UNIT (SCPU®). The exclusively developed motor and control unit ensures an optimized soldering profile and thus even better soldering results. Individual zones can be controlled individually, allowing perfect adaptation to the requirements of material and solder paste.

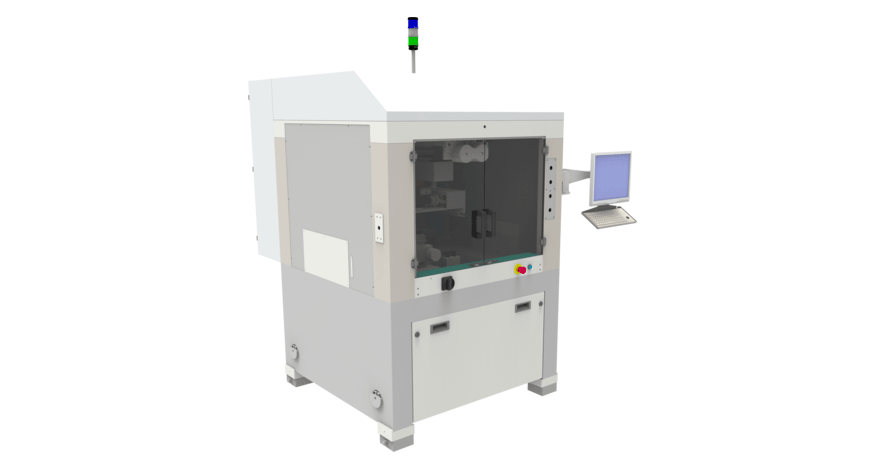

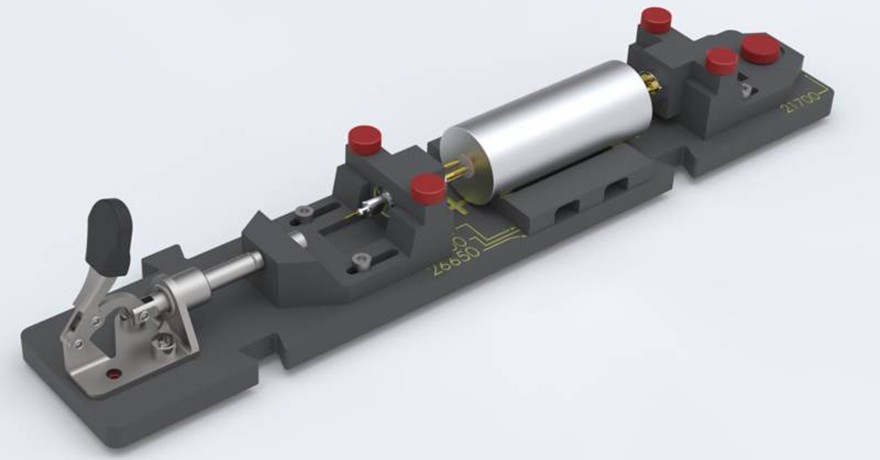

IPTE - SpeedRouter

The depaneling system SpeedRouter is developed for high-volume depaneling for production lines with short cycle time.

The SpeedRouter features fast product change-over through the exchange of a product-specific gripper.

Routers and/or saw blades are at hand and guarantee an optimal depaneling of the PCB.

Link to the product SpeedRouter

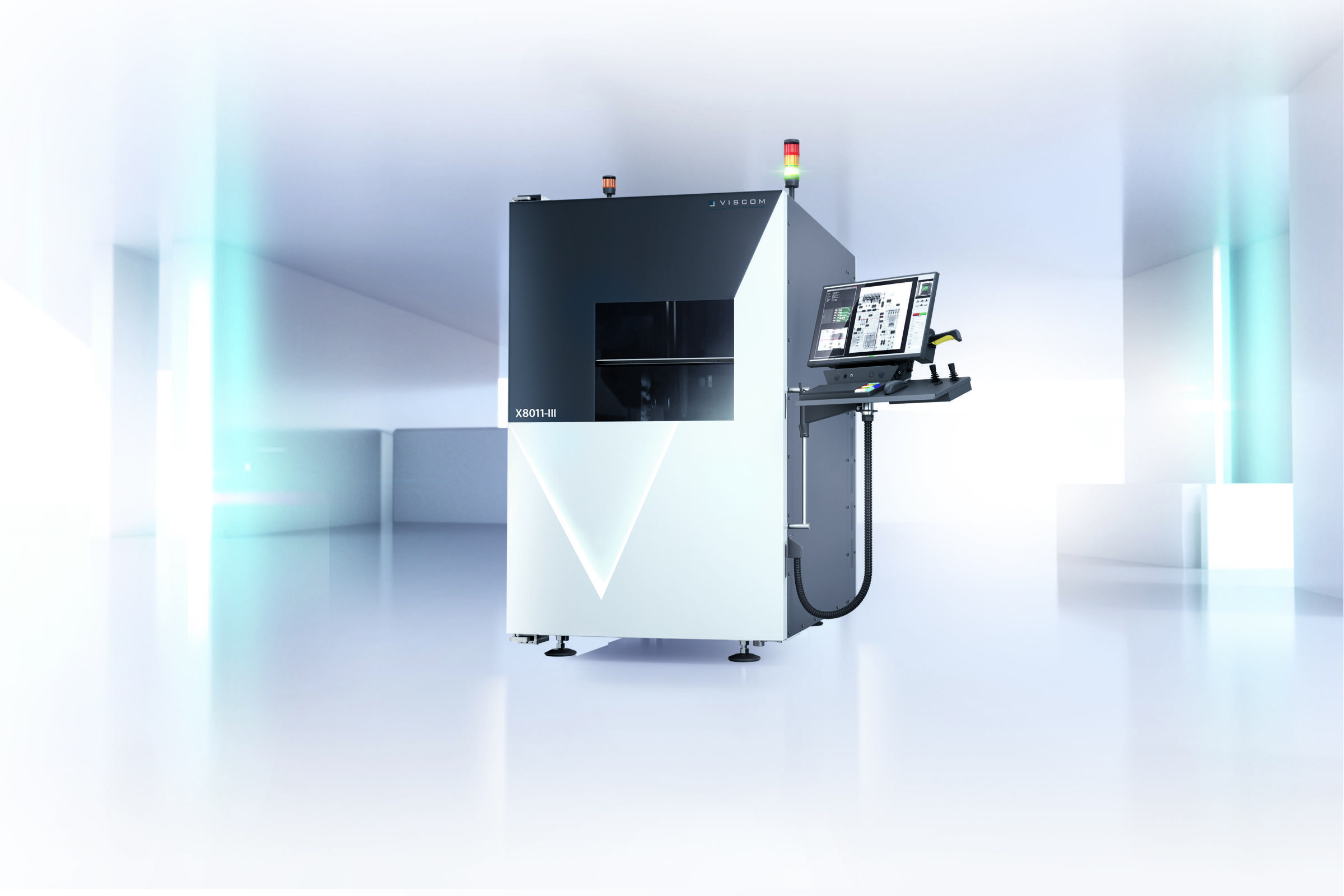

Viscom - 3D MXI System X8011-III: New Team Player for Universal X-ray Use

Viscom AG continues its success story in the field of manual and automated X-ray inspection (3D-MXI) with a new high-quality system: like its predecessor X8011-II PCB, the X8011-III offers outstanding flexibility in inspection tasks and extremely high resolutions – plus brilliant and highly detailed image quality.

At Viscom's vVerify verification station, 3D MXI inspection results can be compared with those from other inspection gates to optimize the process.

The heat map provides detailed information about the radiation dose on the system or as part of an automatic test report.

Link to product 3D MXI System X8011-III

BOFA - AD Oracle iQ2

The huge success of BOFA’s unique Intelligent Operating System (iQ) established a step change in the performance of fume extraction technology. iQ2 builds on this and incorporates a range of new and highly advanced feature enhancements to transform your productivity.

https://www.youtube.com/watch?v=994sZm08S9A

Viscom - iX7059 Heavy Duty Inspection

Fully Automated Inline X-ray System with Special Rapid Transport for Heavy Assemblies on Goods Carriers

The new iX7059 Heavy Duty Inspection X-ray system is part of Viscom’s brand-new iX series for fast, fully automated inline X-ray inspection. The company developed a special transport system for the handling of workpiece carriers and soldering frames to ensure that heavy and encased assemblies can be transported and inspected in optimized cycle times. This special system can transport assemblies with dimensions of up to 500 x 500 mm and a weight of up to 40 kg. As a result, automatic X-ray inspection is gaining a foothold in trending sectors such as electric mobility, network infrastructure for the 5G telecommunications standard and in the area of renewable energies.

In order to ensure 100% product quality in high current and high voltage electronics, the heat generated as a result of the high currents has to be dissipated in a reliable manner. Large cooling elements, massive wire solder joints and power components, for example, are used to this end. Insufficient solder joints or voids within the soldering area can cause overheating in this situation and put the functionality, safety, and efficiency of the system at risk. A fully automated inline X-ray inspection that can be flexibly deployed for 2D, 2.5D, and 3D analyses is the first choice for reliable inspection.

The iX7059 Heavy Duty inspection system impresses with a resolution extending from 8 μm to over 30 μm, depending on the configuration. The complex inspection objects are irradiated with 130 kV or optionally 160 kV. The broad inspection scopeof the inspection system extends to soldering defects, damage, twisted, missing, or incorrect components as well as concealed voids, blow holes/voids in surface solder joints and the degree of filling of THT solder joints.

The new “Evolution 5” image acquisition approach with the new T3 generation of flat panel detectors is used for highly accurate and fast 3D X-ray inspection. In combination with powerful computed tomography, all key defect features in sectional images are visualized in high detail to enable precise, convenient error detection. This simplifies verification, reduces false alarms, eliminates reworking and prevents product waste. Convenient operation of the system with the modern touchscreen monitor and fast, easy setup of inspection programs via the vVision or EasyPro operating software put the finishing touch on the system concept.

The compact, space-saving iX7059 Heavy Duty Inspection comes in a completely new system design that combines a distinctive style with high-quality materials and a robust housing. The system can also be seamlessly integrated into the production or final assembly line, and networking to implement smart factory concepts is also an option.

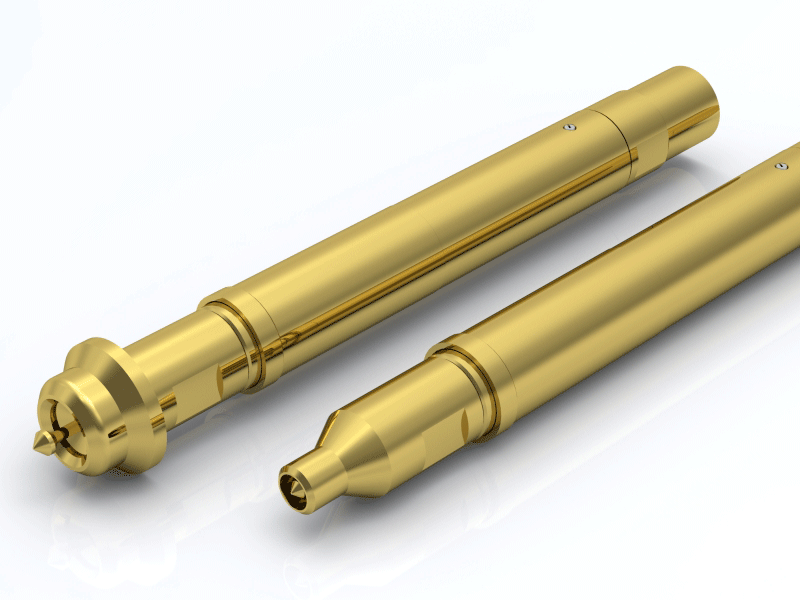

Feinmetall - expandable cell adapter for contacting round cells

Expandable cell fixture for contacting round cells of the type 18650, 21700 and 26650. By changing different exchangeable inserts, it is possible to meet the different requirements for current intensity and contact quality.

https://www.youtube.com/watch?v=rUgA3pnmgQE&list=PLzYBphLWkM_zarglsJHvpQEFp22Rc4jg9

Feinmetall - new RF Contact Probes for High Frequencies up to 16 GHz

For the contacting of RF connectors Feinmetall's contact probes have already proven in practice for years. The contact probe series HF860 has been developed for these applications and offers reliable signal paths for RF test environments.

However, what if higher frequencies are demanded, like for example in 5G applications?

For these applications, Feinmetall has now developed the new HF890 contact probe series. It offers the same outer dimensions as the established HF860 series, but it is optimized for higher frequencies.

The advantages

- Excellent operating range up to 16 GHz

- Suitable for testing networked devices

- Even suitable for 5G applications

- Proven design for long lifetime

- Easy connection via SMP connector

- Easy mounting with suitable receptacles

Specifications

- For MMPX (Female): HF89002B0001G

- For MMBX und SMA (Female): HF890002B0002G

- For MSMP (Male): HF89005B0003G

Further versions on request.

The perfect contacting solution for your RF application

You will find all current RF contacting solutions also for your field of application in our RF CONTACT PROBE OVERVIEW.

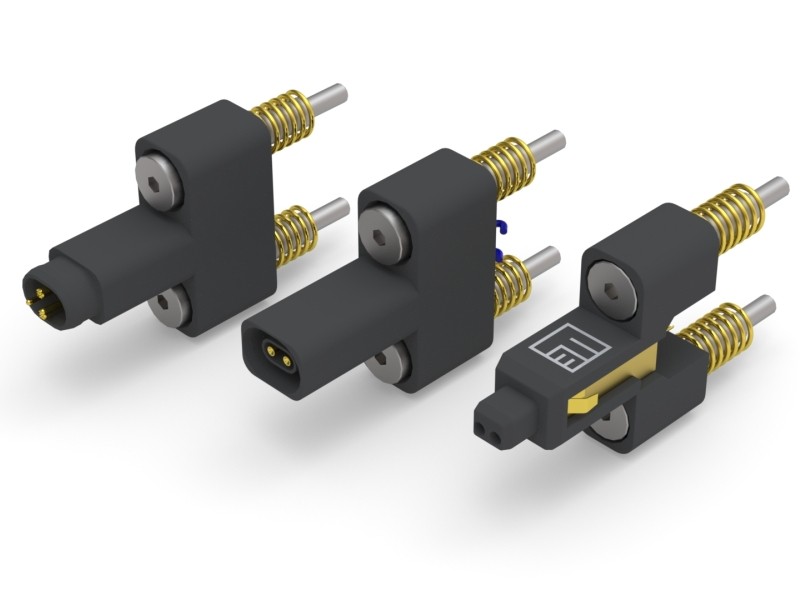

Feinmetall - TC77, Test Connectors for electrical contacting of H-MTD and MATEnet

The contacting of on-board networks and systems always brings new requirements for testing and contacting technology. For radio-frequency signals, some connectors have established on the market, for example the connector types H-MTD and MATEnet.

Contacting solutions for H-MTD and MATEnet

For tests with radio-frequency signals, a suitable high-quality and RF-optimized contact design is required. Feinmetall offers appropriate solutions for this application with the HF77 contact probe series. However, for simple electrical tests, more economical contacts are required as well.

Economical and simple electrical contacting

This is why Feinmetall has developed test connectors for this application, allowing reliable electrical contacting, combined with very simple and flexible mounting. The new test connectors of our TC77 series reliably contact the signal and ground pins. They are perfectly designed for this application with spring-loaded internal contact probes. The mounting can be realized by a flange and the connection of the test connector can either be done by a cable or soldered.

Compensation of tolerances

By providing a wobble function in the test connectors, certain tolerances in the positioning of the DUT can be compensated. Such a wobble function has already proven itself for the RF contact probes and has also been implemented in the test connectors.

Feinmetall offers comprehensive and economical solutions

With these test connectors, Feinmetall completes the contacting solutions for automotive technology and offers customers the most suitable and economical contacting solution for all applications.

The following versions are currently available

- MATEnet: TC77 MATEnet-M 01 LA S

- H-MTD-Male: TC77 H-MTD-M 01 DR S

- H-MTD-Female: TC77 H-MTD-F 01 DR S

Viscom - S3088 ultra chrome SPI

Ultimate quality thanks to early defect detection

Checking all the relevant points in the production process is essential, especially in terms of analyzing the causes of defects, fixing them, and – most importantly – preventing them in the future. That’s why solder paste printing is of fundamental importance for manufacturing complex assemblies: If paste printing isn’t performed correctly, the defect can impact the subsequent assembly and the soldering process, resulting in a tilted component or a poor or missing solder joint.

Optical inspection systems designed for solder paste inspection (SPI) quickly and reliably check the solder paste deposits on the circuit board. They measure the following defect features: surface, height profile, and volume. The measurement and image data from the SPI can be fed back to the solder paste printer (closed loop) and simultaneously transferred onto the automatic placement machine (closed forward loop) so it can adjust the placement position to the actual solder paste printing. Situations in which components are still assembled on the target position despite offset solder paste are critical because this results in a risk of a lifted lead without electrical contact or tombstoning. Solder paste defects such as offset paste, insufficient paste, or bridging are some of the typical defects that the SPI detects. This makes it possible to draw conclusions on improving cleaning cycles, correcting offsets, or even eliminating weak points in the PCB design.

Taking efficiency to the next level

Viscom’s 3D SPI systems work at maximum speed and precision to inspect the solder paste application even for the most demanding assemblies. All essential 3D defect features are recorded and checked, such as volume, height, and form as well as surface area, displacement, and paste smearing. Thanks to the Viscom Quality Uplink feature, inspection data from all inspection systems in the line is displayed at a glance at the verification station, allowing process analysis and optimization almost in real time.

Feinmetall - new RF Contact Probes for Limited Space

For the contacting of RF connectors such as SMB, SMC, Fakra and others, Feinmetall's contact probes have already proven in practice for years. The contact probe series HF860 has been developed for these applications and offers reliable signal paths for RF test environments.

However, what if the space conditions do not allow the use of the HF860 probes?

For these applications, Feinmetall has now developed the new HF830 contact probe series. It offers the same performance as the established HF860 series in a significantly more compact design.

The Advantages

- excellent operating range up to 6 GHz

- easy connection via MCX connector

- Connection cable available

- easy mounting with suitable receptacles

Specifications

- for SMB (Male): HF83005B0002G520

- for SMC (Male): HF83005B0001G520

- for Fakra (Male): HF83005B0003G540

- for Fakra (Female): HF83002B0004G490

Further versions on request.

The perfect contacting solution for your RF application

You will find all current RF contacting solutions also for your field of application in our RF CONTACT PROBE OVERVIEW.

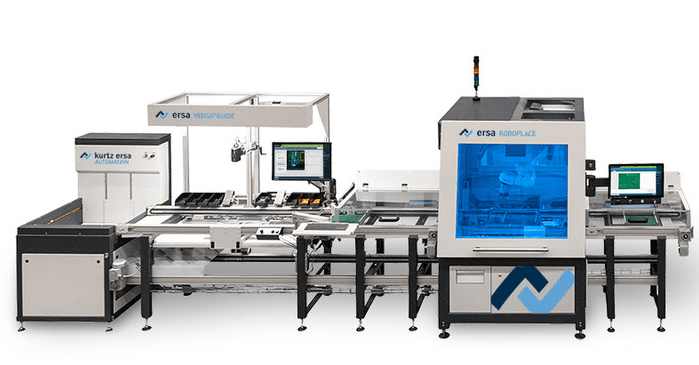

Ersa - Zero defect challenge starts with assembly placement

Achieve a higher first yield (FPY) directly in your electronics production - with the new optical Ersa placement inspection VERSAGUIDE PRO. Because there are many sources of error, for example a large number of different components, different assemblies or even changing layers. With VERSAGUIDE PRO, you ensure a stable, reproducible process and eliminate errors before they can even occur. Train your plant team on it - you will see how motivation increases and performance goes up!

https://www.youtube.com/watch?v=_sOyI2iDPV0

In the highest configuration level VERSAGUIDE ULTRA offers extensive possibilities to design the placement process in the best possible way. With the 640 x 480 mm field of view, codes and OCR can be read directly through the camera and made available for subsequent processes. The included IO module ensures process interlocking - the next process steps only take place after VERSAGUIDE PRO/ULTRA has checked the assembly 100%. Optimal illumination is provided by a large lighting panel with 18 MP camera.

Ersa testing downstream

In order to be able to assess the entire process, Ersa offers VERSAGUIDE PRO/ULTRA, an assistance system for correct assembly not only before the soldering systems. After the soldering process, VERSAEYE makes it possible to view and classify a solder joint via 360° all-round view, thus ensuring that the highest quality requirements are met for the assemblies.

Leutz moves to new location

For more than 20 years, Leutz Lötsysteme GmbH in Hochdorf has been your reliable contact for innovative and individual soldering systems.

In order to continue to be a qualitatively strong partner for new technologies and innovations in the future, a new company building was constructed in Albershausen this year and occupied in October.

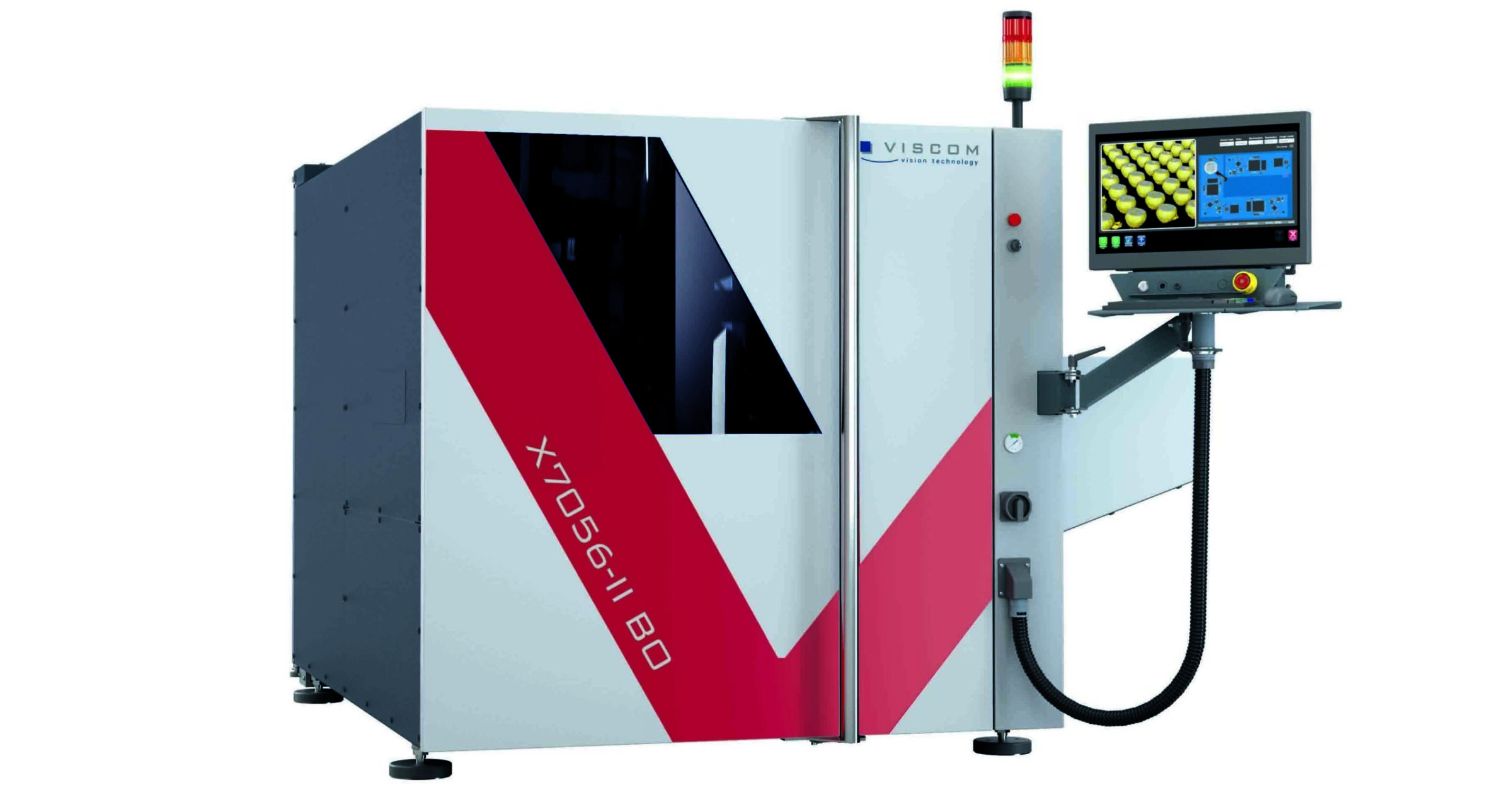

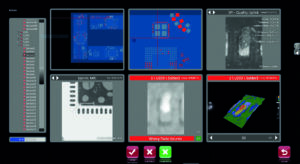

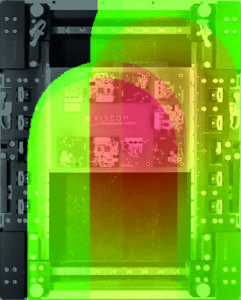

Viscom - New inline X-ray system X7056-II BO for high-throughput wire bond inspection

The role of power electronics is becoming increasingly decisive in the automotive sector, especially for electric drives. Smooth functioning and long service life of power electronics ensure the necessary product safety and also the desired energy efficiency of electric vehicles and hybrids. In addition, new types of sensors and cameras provide even better protection for vehicles during operation. The new Viscom system X7056-II BO, which inspects bond wires optically and radiographically in an inline system at maximum inspection depth, ensures comprehensive inspection of power semiconductors and encapsulated sensor elements alike.

The new X7056-II BO inline system effectively combines optical wire bond inspection with X-ray inspection to reliably and precisely inspect even encapsulated wire bonds and concealed solder joints underneath chips. The unique combination of AOI and AXI in a single system ensures high-throughput handling to meet the highest cycle time requirements at maximum inspection depth.

Ribbons, thick and thin wires are inspected, as well as the soldering quality of dies. Thanks to the high-resolution sensor technology, the inspection scope covers all bond points and wires, open and concealed connection points, so that the quality of wire runs, dies and component layers, damage and position deviations as well as voids in surface soldering are detected with absolute certainty. For very effective test program generation, the standard library contains all relevant test samples for die bonds, ball-wedge, wedge-wedge and security bonds.

With the new bond inspection system, Viscom offers an ideal solution for the increasing demand for X-ray inspection in the bond area. The system is designed for use in the production of high-end electronics and is ideal for installation in final assembly for power electronics, circuits, sensor construction and packaging to ensure 100 % quality control. Viscom's offering is rounded out by powerful verification and evaluation of statistical process control.

Feinmetall - Expansion of the portfolio for e-mobility and high-frequency measurements

The demand for solutions for the testing and inspection of charging plugs and charging sockets in the e-mobility sector is increasing, as is the demand for high-frequency plugs. Feinmetall therefore offers many innovative solutions.

More and more the field of e-mobility is finding its way into the various markets in Europe, the USA and Asia. There is therefore also a growing demand for solutions for testing and checking charging plugs and charging sockets.

For this purpose we offer a variety of solutions for current transmission, voltage measurement and the position of the finger protection on the test object.

The new 20-page flyer offers a comprehensive but compact overview of all FEINMETALL high frequency pens. Now also with the new solutions for H-MTD-Marks, SMP-Marks, Fakra-Marks and MATEnet.

Modular high-performance SMT placer

The highly efficient, modular premium SMT placer YRM20 from Yamaha Motor Europe is based on a completely new platform that reflects the intelligent factory.

This platform uses two different head types: A newly developed high-speed multi-purpose rotary head (RM), which in combination with the new high-speed feeder offers a world-leading placement capacity (under optimal conditions) of 115,000 CPH, and a single-head solution via the newly designed in-line head (HM), which combines high speed with high versatility. With a placement accuracy of ±25 µm (Cpk ≥1,0) it supports the assembly of microchip components of size 0201 (0.25 mm x 0.125 mm).

In addition, the newly developed transport system can accommodate a maximum panel width of 510 mm. The optimized layout improves the transfer speed and significantly reduces the time required for changing the blank. The adoption of the overdrive drive technology from the modular Premium series, which has been used to achieve highly efficient production, reduces the restrictions on placement head access when the front and rear table sides obstruct each other. In addition, the graphical user interface has been redesigned to further simplify intuitive operation.

A completely new approach for the placement head was chosen for the development of the efficient, modular premium placement machine. The machine combines the two technologies, the Sigma series rotary head and the YSM series inline head. The 1-head solution achieved can process all component types, from ultra-small chips to large components, without changing the head.

The SMT placer uses a new machine control system that is ready to serve a new era of increasing data speed and volume requirements in production facilities. The fast and robust application software interacts seamlessly and securely with peripheral systems and external software.

Soldering technology specialist Kurtz Ersa focuses on automation concepts

To this end, a well-coordinated Kurtz Ersa team of engineers has been working intensively for three years to develop intelligent solutions for automation projects in industrial production. After the change of name at the start of 2020, "Kurtz Ersa Automation" will now become the official and central contact point for automation competence within the Kurtz Ersa Group. On the one hand, as in previous years, automation concepts will be realized with the in-house, established brands Kurtz and Ersa, and on the other hand, the existing know-how in automation technology will now be made available to the international market of various industries. An example of this is a current project from the automotive industry for a fully automated solution in the field of electronic module assembly including the integration of Ersa soldering technology. All in all, a holistic turnkey solution, realized with proven, robust components and systems from the Kurtz Ersa Group.

Whether internal or external - as a fully-fledged member of the experienced machine manufacturer Kurtz Ersa, Kurtz Ersa Automation delivers precisely fitting systems that convince in terms of functionality, quality and adherence to delivery dates. Kurtz Ersa Automation focuses on the automation of complex assembly and testing processes, taking into account the logical aspects of meeting the requirements of Industry 4.0.

With the concentration on automation technology, there is also a change in the management at the Wertheim location: Ersa Managing Director Ralph Knecht is now once again devoting himself primarily to his tasks for Ersa GmbH and is handing over his responsibilities regarding the former Conline GmbH to Olaf Klink, who is taking over the function of Managing Director of Kurtz Ersa Automation GmbH. Since the beginning of January 2020, Olaf Klink has been concentrating primarily on the strategic and sales issues of Kurtz Ersa Automation GmbH. The 51-year-old has 20 years of specialist and management experience in the automation sector on the international stage, including major successes in the automotive industry. Olaf Klink brings along the knowledge that Kurtz Ersa Automation needs for its new orientation. "Treat the impossible as if it were possible" is the credo of the native Osnabrücker. This bon mot, which goes back to Goethe, is symbolic of the Kurtz Ersa Automation approach to approach future tasks and position itself in automation technology as a solution provider for complex tasks. The demand for complex, far-reaching and holistic automation systems is unbroken. Kurtz Ersa Automation will exploit the future potential that lies in automation technology.

Thank you for visiting the productronica 2019

Our 12-strong sales and service team was on duty for you and 20 of our partners for four days. Many conversations could be held, new projects could be concretized and business relations could be intensified.

We thank you very much for your coming and your interest.

Our partners on site:

| Altix | Interflux | ||

| Asscon | IPTE | ||

| ATG Luther&Maelzer | Leutz | ||

| ATX | SAT | ||

| cab | Schmid | ||

| Christian Koenen | Taiyo | ||

| DuPont | Totech | ||

| Ersa | Viscom | ||

| Feinmetall | VisiConsult | ||

| Inmatec | Yamaha |

New Production Facilities in Herrenberg

Feinmetall has invested in a new production hall at its Herrenberg site. At the beginning of 2018, all work steps related to the mechanical processing of metal are accommodated in the new building.

This creates space in the main building for further automation. In total, Feinmetall has invested around two million euros in the new production facilities in Herrenberg.

New partner - cab

Stepan increased its portfolio and offers cab's supporting tools.

Stepan is proud to announce the collaboration with the German company cab.