New 3D X-ray system from Viscom: extremely fast handling coupled with high inspection depth

Very short handling times in combination with outstanding image quality and expanded inspection depth predestine this X-ray inspection system for use in high-end electronics production.

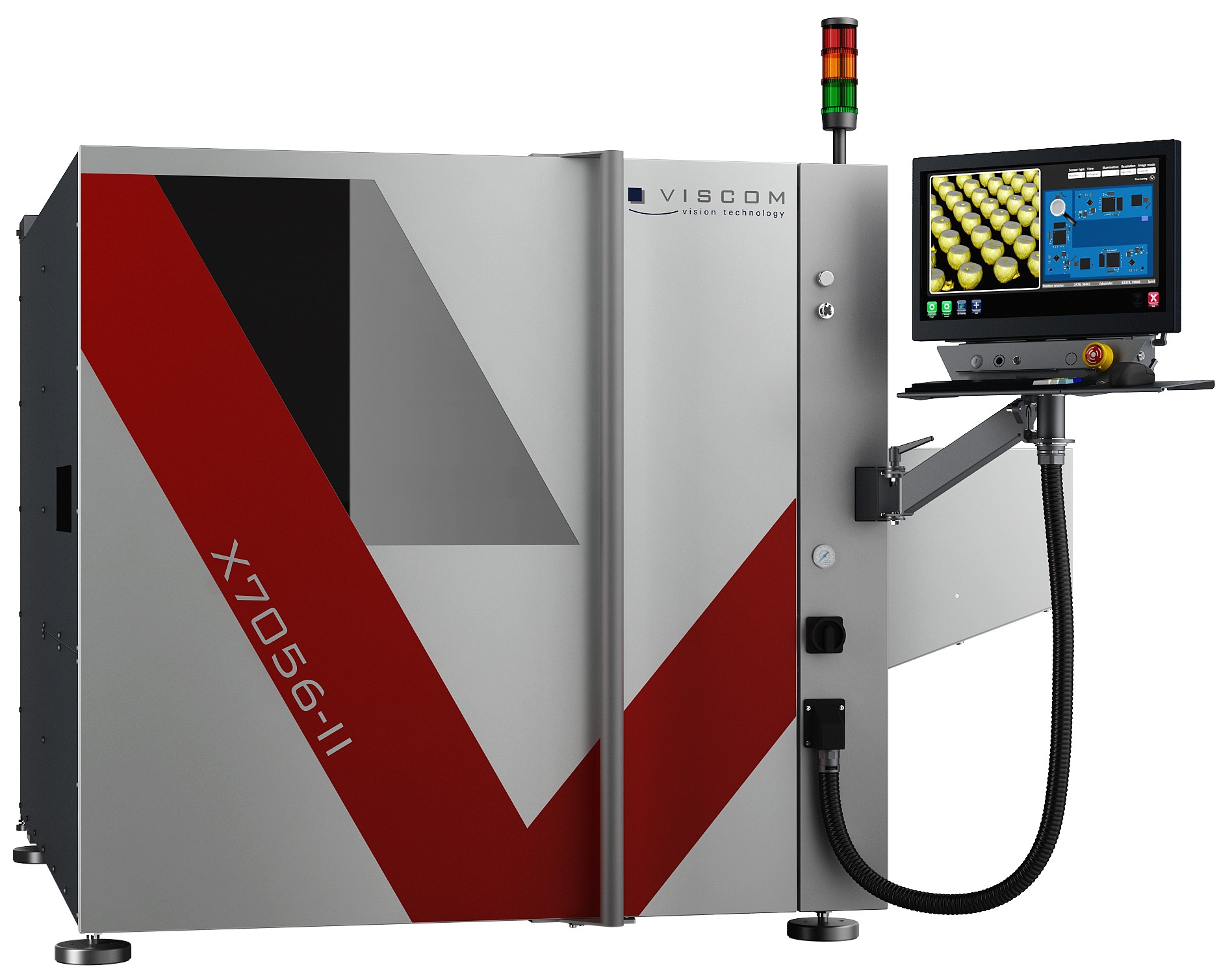

The X7056-II system with automatic X-ray inspection (AXI) in the 3D variant guarantees high inspected product quality. A special highlight is the fast transport xFastFlow. Additionally, Viscom will present the new 3D AXI calculation procedures with the vVision operating software for the first time at SMT Nuremberg. The X7056-II offers an extraordinarily high 3D image quality that shows interfering structures considerably reduced. Together with fast handling, the X7056-II is the optimal solution for sophisticated 3D inline X-ray applications.

Based on FastFlow, the fast handling option for Viscom AOI systems, a fast concept for handling is now available for X-ray inspection: With xFastFlow, the system is ideally suited for use in production lines that require high throughput despite extensive inspection of hidden solder joints. Through use of xFastFlow, the time needed for component infeed and outfeed is cut by more than half, and up to four boards can be in the system simultaneously. Due to the time saved, 3D inspections, which used to be done selectively, can be expanded to cover far more than just individual components.

By taking advantage of the third dimension, users have the benefit of an unshadowed view of components and hidden solder joints. The X7056-II, with the help of the planar CT, can automatically resolve any covered areas on double-sided printed circuit boards to clearly reveal important defect features and allow exact evaluations. During periods of high packaging and placement densities, this results in fewer false calls and so more efficient production. This also makes program generation simpler.

The hardware components of such a system must be selected carefully. A powerful flat panel detector, movable on an xy-table, ensures first-class 3D image quality. As the number of acquisitions increases, the precision of the required calculations also rises. This is flexibly determined according to the type of main application to achieve an optimal compromise between cycle time and inspection quality. A big advantage over familiar, rigid detector solutions is the ability to employ 2D and 3D inspections on a component, both selectively and combined. In particular, the optimized image acquisition positioning results in a further increase in speed or – optionally – an even better image quality. The system, like its predecessors, can be expanded to an AOI/AXI combination system.

Trade fair visitors will be convinced: The combination of fast programming, extremely high 3D image quality and intuitive operating concept makes the X7056-II a successful system advance in the area of 3D X-ray inspection.